Handheld scanning for pipework replacement

-

LocationNorth Sea, UK Sector

-

CustomerH&P

-

Time Scale2023

-

DetailsAsset Integrity – Brownfield Modifications

Scope

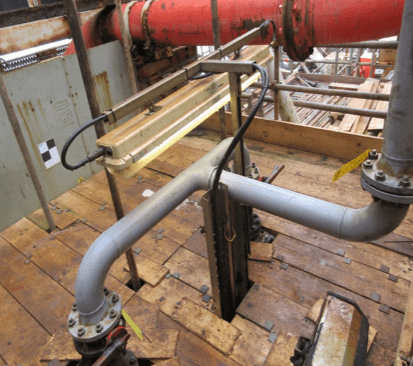

We supported the integrity of an offshore fixed platform in the North Sea by delivering our innovative Handheld Scanner solution to survey a section of piping.

Our portable scanning solution is designed to support modifications through delivering highly accurate digital replicas and 3D dimensional data, with precision down to half a millimetre for model generation and fabrication.

Overview

Digital precision for offshore piping replacement

Working with our sister-company, H&P on an UK offshore platform it manages, we deployed our Handheld Scanners to capture scan data to replace a brine pump discharge line.

The data was transferred onshore, enabling rapid generation of fabrication isometrics through advanced scan-to-isometric techniques. Once approved, the isometric drawing was issued for quotation, and the selected vendor proceeded with fabricating the piping spools. Following rigorous quality checks, the pipework was shipped to the platform and installed by the crew.

Real-time data visualisation, combined with a semi-automated design workflow powered by our comprehensive piping specification databank, ensured a streamlined and dependable outcome.

The tool eliminated the need to mobilise a surveyor to the asset and removed unnecessary downtime for initial investigations, enabling prompt response times and reducing overall disruption.

Performance objectives

- Scan files enabled rapid engineering and fabrication.

- Quick and efficient repair of a defect in a brine pump discharge line.

- Easy-to-use point and press system, operated by the drill crew.

- Used for like-for-like replacement, upgrade and modification.

- Scan to 3D model software speeds up the process of isometric production, P&ID reviews and hose management.

- Overall reduction to costs, lead times, personnel on board and non-productive time.

Accuracy of 0.5 mm at 1 m ensures engineering precision.

Precision delivered fast

- Within a day we can turn the laser scan into a model and subsequent fabrication drawings

- Accuracy of 0.5mm @ 1m assures engineering drawing precision

Compliance and standards

- ASME B31.3 Process Piping

Safety and reliability

- Developed through extensive experience across multiple projects by our engineering teams and offshore maintenance crews.

- Digital technologies reduced risk of failure to fit.

- QA checks ensured first-time fit with no offshore modifications required.

- Offshore crew performed scanning, eliminating the need for a survey team.

Local delivery

- Offshore crew empowered to perform scanning

- Rapid turnaround due to HHS technology.

- The solution fosters collaboration across maintenance, operations, and engineering teams, and is supported by a dedicated help desk.

Scanner weight – 1.48 kg, highlighting ease of use offshore.

Handheld scanner specifications

- Scanner dimensions – 285 mm x 256 mm x 130 mm

- Weight – 1.48kg

- Range (min/max distance) – 0.5mm at 1m/15 mm at 10m

- Power/connectivity – HDMI, USB 3.0, Wi-Fi

- Peli case dimensions – 500 mm x 370 mm x 200 mm

- Peli case weight (incl. kit) – 7kg

Explore more

Related pages

Maximum Service.

Minimum Disruption.

Speak to one of our specialists to find out how a customized service agreement can help keep your equipment running.